SD-GF35

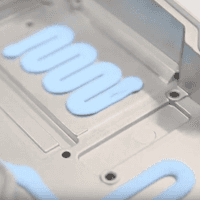

SD-GF35 is a two-component thermal interface material, cured at room or elevated temperature, featuring ultra-high thermal performance and superior softness. SD-GF35 with 3.5W/m·K thermal conductivity is a good solution for interfacing fragile components with high topography and/or stack-up tolerances to normal heat sink or housing. After cured, SD-GF35 remains a low modulus elastomer to help relieving stress during application and prevent pump-out from the interface. SD-GF35 is with lightly stickiness but not designed to be a structural adhesive.

Features and Benefits

- Thermal conductivity: 3.5 W/m·K

- Ultra-conforming, designed for fragile and low-stress applications

- Ambient and accelerated cure schedules

- Excellent low and high temperature mechanical and chemical stability

Typical Properties

| PHYSICAL | TYPICAL RESULTS | TEST METHOD |

|---|---|---|

| Color , Part A/B | White/Blue | Visual |

| Viscosity as Mixed | 1,000,000 mPas | ASTM D2196 |

| Density | 3.1g/cc | ASTM D792 |

| Mix Ratio | 1:1 | - |

| Shelf Life @ 25°C | 6 months | ASTM D412 |

| PROPERTY AS CURED | ||

| Color | Blue | Visual |

| Hardness, Shore 00 | 35 | ASTM D2240 |

| ELECTRICAL AS CURED | ||

| Dielectric Strength | 7kV/mm | ASTM D149 |

| Volume Resistivity (Ω·cm) | > 10¹⁰ | ASTM D257 |

| Flame Rating | V-0 | UL 94 |

| THERMAL AS CURED | ||

| Thermal Conductivity (W/m·K) | 3.5 | ASTM D5470 |

| CURE SCHEDULE | ||

| Pot life @ 25 °C | 60 mins. | |

| Cure @ 25 °C | 24 hrs. | |

| Cure @ 120 °C | 30 mins. |

Typical Applications

- Automotive electronics

- Computer and peripherals

- Between any heat-generating semiconductor and a heat sink

- Telecommunications

- Thermally conductive vibration dampening

Available Forms

- Supplied in cartridge or barrel

Contact us to have your questions answered, to obtain free samples, arrange prototypes/small batch runs, and discuss customized solutions for your projects.