SD-PG10

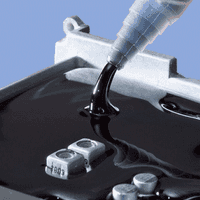

SD-PG10 is a 2 part addition cure silicone. For easy application the product was designed with very low viscosity.

It cure at room temperature but it is possible to accelerate the speed by heat.

Thanks to its long term thermal resistance (-50°C up to 180 °C ) SD-PG1.0 is successfully used as potting glue for protection and encapsulation of electrical sensitive devices and connections, LED`s lighting housings, power modules, high voltage electrical components as well as high load resistors, etc.

SD-PG1.0 is flame retardant.

Features and Benefits

- Thermal conductivity: 1.0 W/m·K

- Two-component, room or elevated temperature curing system silicone

- Low viscosity and high flow

- Excellent low and high temperature mechanical and chemical stability

Typical Properties

| PHYSICAL | TYPICAL RESULTS | TEST METHOD |

|---|---|---|

| Color / Part A | White | Visual |

| Color / Part B | Black | Visual |

| Viscosity / Part A | 3,000 mPas | Brookfield 4# 20rpm |

| Viscosity / Part B | 3,000 mPas | Brookfield 4# 20rpm |

| Viscosity as Mixed | 3,000 mPas | Brookfield 4# 20rpm |

| Density | 1.85 g/cc | ASTM D1875-2003 |

| Mix Ratio | 1:1 | - |

| Shelf Life @ 25°C | 12 months | - |

| PROPERTY AS CURED | ||

| Color | Black | Visual |

| Hardness, Shore A | 45 | ASTM D2240 |

| ELECTRICAL AS CURED | ||

| Dielectric Strength | 18kV/mm | ASTM D149 |

| Volume Resistivity (Ω·cm) | ≥ 1x10¹⁰ | ASTM D257 |

| Flame Rating | V-0 | UL 94 |

| THERMAL AS CURED | ||

| Thermal Conductivity (W/m·K) | 1.0 | ASTM D5470 |

| Pot life @ 25 °C | 60 mins. | - |

| Cure @ 25 °C | 24 hrs. | - |

| Cure @ 100°C | 30-60 mins. | - |

| Working Temp. | -50-180°C | - |

Typical Applications

- Automotive electronics

- Power supplies

- Connectors

- Sensors

- Industrial controls

- Transformers

- High voltage resistor packs

Available Forms

- Supplied in 20KG barrel

Contact us to have your questions answered, to obtain free samples, arrange prototypes/small batch runs, and discuss customized solutions for your projects.